Roofing plays an essential role in protecting your family and your home. It also defines your home's exterior aesthetics. You want (and need) a properly installed, durable roofing product that can stand up to wind, flying debris, hail, and excessive moisture and temperature in order to limit repair, maintenance, and replacement costs. We have compared two roofing products — asphalt shingles and synthetic slate roofing, by cost, longevity, durability, installation problems, weather resistance and shingle deterioration to help you find the perfect roof to keep your home and family safe for many years to come.

Strip Asphalt Roofing

At the start of the 20th century, contractors began using asphalt shingles, replacing the commonly used wood, slate, and clay shingles. The H.M. Reynolds Company of Grand Rapids, Michigan (often cited as the inventor of asphalt roof shingles), produced the rolled asphalt roofing coated with slate granules which became widely available by 1910, replacing the costly wood shingles that lacked fire resistance. Today, asphalt shingles cover the roofs of four out of five homes in the United States. Asphalt shingles have evolved into two products: the most commonly used, fiberglass, and the less common, organic-based.

Fiberglass Shingles

Fiberglass shingles contain a thin mat of glass fibers of varying lengths and orientations. The base surface has a specially-formulated asphalt coating, with weather-resistant mineral granules and adhesives for adherence.

Organic asphalt shingles

Organic asphalt shingles contain a base (mat or substrate) made of cellular fibers, like recycled wood fibers and waste paper, saturated with a specially formulated asphalt coating that is surfaced with weather-resistant mineral granules and adhesives for adherence.

Asphalt shingles are one of the least expensive roofing products on the market and come in many colors and styles, fitting a wide variety of home styles. Lightweight and easy to cut, they are relatively easy to install, requiring little prep work and no special tools. Depending on the job size, installation of an asphalt shingle roof can take one to two days. Moreover, easy to repair asphalt shingles allow you to replace shingles one at a time.

Algae Concerns

Algae can occur on any shaded asphalt roof, particularly in warm, humid conditions, detracting from your home’s overall appearance and lowering the resale value. Algae can block the reflective properties of your shingles, increasing your energy bills. It can also weaken the shingles by deteriorating the limestone granules. Over time, the algae will combine with fungus to form destructive lichen, which can lead to moss taking root and destroying the integrity of the entire roofing system.

Are Asphalt Shingles Eco-Friendly?

Asphalt shingles contain recycled paper, however, their high asphalt content makes them less eco-friendly. Asphalt, a semi-solid form of petroleum, wastes a lot of energy and produces greenhouse gas emissions. The U.S. generates approximately 11 million tons of asphalt shingle waste annually, which will remain there for 300 years. However, some fiberglass shingles incorporate solar reflective asphalt, which helps stop the Sun's rays from heating up the inside, saving on energy and contributing to an eco-friendly building or home.

Common Types of Asphalt Shingles

Three-tab and laminated strip asphalt shingles are the most common roofing types used on homes with roofs that have a pitch greater than 2/12 (9.5 degrees); however, they are best suited for a slope of 4/12 (18.5 degrees) because of vulnerability to wind-driven rain. Homeowners most commonly select the three-tab shingles for their low price: however, contractors prefer the more durable and aesthetically-pleasing laminated shingles.

Three-Tab Asphalt Shingles

Three-tabs shingles are made from a single layer of asphalt and have a flat appearance. The three uniform cutouts, or tabs, along the lower edge of the shingle, make it look like three pieces when installed, but it's only one. Cost Per Square (to cover 100 sq. ft. of roofing): $55 to $85 per square. Warranty: 20- to 30-years. Weight (pounds per square): 200 to 250 pounds per square (pps). Wind Resistance: up to 60 miles per hour.

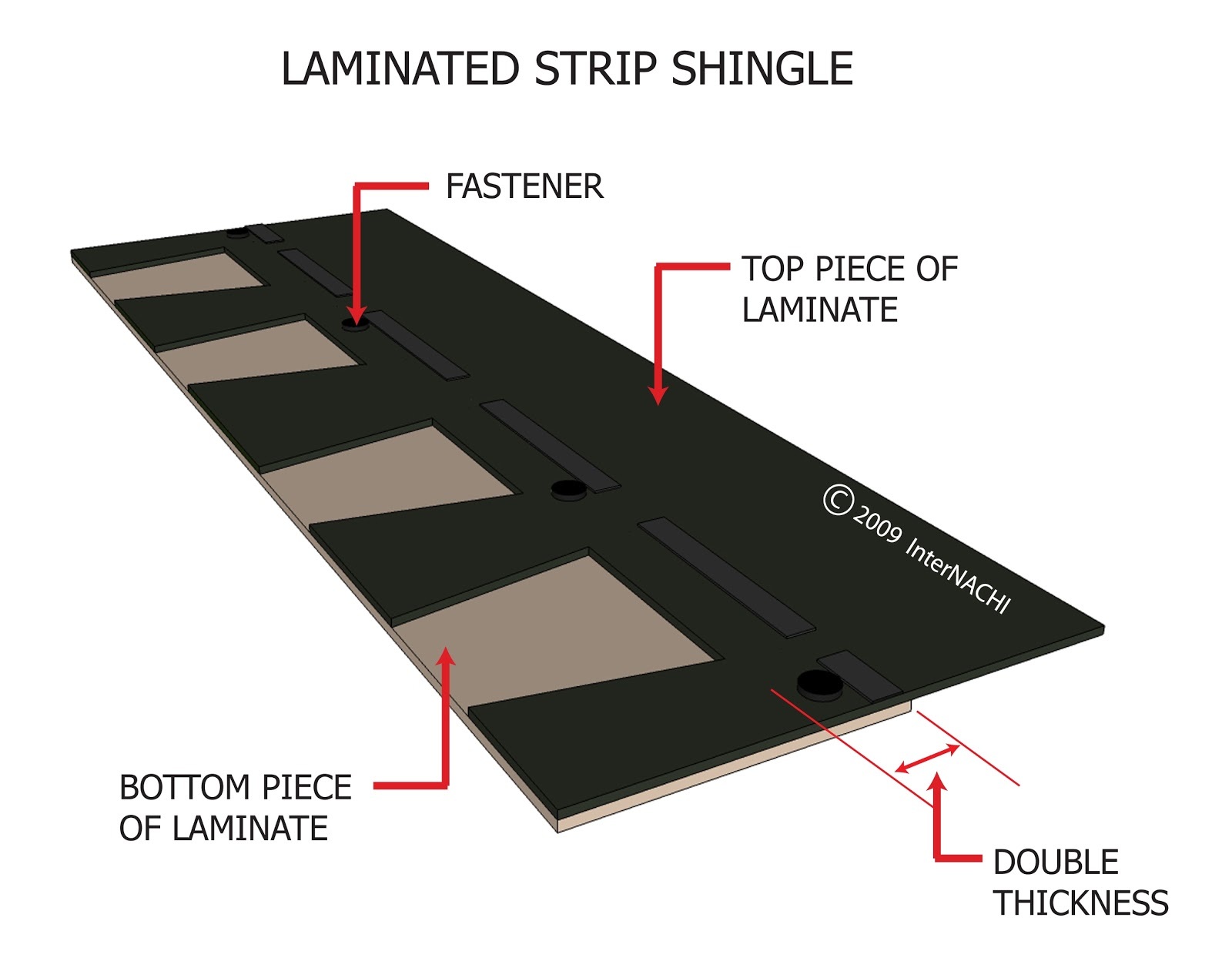

Laminated Asphalt Shingles

Builders, architects, and homeowners use laminated asphalt shingles for their strength and beauty. Laminated shingles have additional layers of tabs (compared to less expensive three-tab shingles), creating extra thickness, weight, durability, and wind resistance. In addition, more granules coat the laminate asphalt shingles than three-tab shingles, adding longevity to the roofing product. The extra tabs also give them a three-dimensional look with varying tones and patterns, mimicking heavier roofing products, like slate. Manufactures laminate both the top and bottom of laminated shingles. The top laminate has a trapezoidal-shaped cutout on its lower half, while the bottom laminate is a solid shingle, half the width of the top laminate. The bottom laminate adheres to the cutouts and a small portion of the upper laminate's solid piece creates a double thickness at this part of the shingle. Cost: $1.65 to $2.50 psf. Warranty: 30- to 50-years. Weight: 250 to 300 pp. Wind Resistance: Maximum of 70 to 110 miles per hour.

Weather-Resistance Issues with Asphalt Shingles: A Case Study After Hurricane Frances

In 2004, Hurricane Frances, a category 4 hurricane, slammed into the southeast U.S., causing $12 billion in damage. Following this disaster, researchers at Texas Tech University and Haag Engineering Company visited the affected area to assess how wind uplifts and flying debris creased, flipped, and displaced three-tab and laminated asphalt roofing shingles. The study compared 129 three-tab shingles and 151 laminated type shingles soon after the hurricane hit, finding that 56 percent of the three-tab roofs suffered damage, while only 13 percent of the laminated roofs appeared damaged. Most of the shingle failure occurred due to creasing, flipping, tearing/removal, and the impact of debris. The study concluded that the wind uplift-resistance of a shingle highly depends on the quality of fastener installation, the sealant's strength, and the asphalt shingle's physical properties (i.e., fastener pull-out strength and stiffness). The study then took a more in-depth look at eleven of the damaged asphalts roofs, detailing specific damage causes. They found that improper installation was the leading cause of roof failure. However, shingle deterioration and weather resistance also played a significant role.

Installation Problems with Asphalt Shingles

Improper installation significantly reduces an asphalt shingle's wind resistance.

Improperly Installed Starter Shingles

The underlying row of shingles (started course) fastens along the roof's edge to resist uplift, then the first shingle course bonds to the starter course of shingles. Starter shingles not securely bonded to the roof can allow relatively low wind speeds to detach shingles. In this photo, starter shingles are not securely fastened at the roof edge.

Shingle Bonding

The sealant strip bonds the asphalt shingles to the roof edge. An asphalt shingle roof acts as a single entity when sealed adequately with sealant strips. The success of the sealant strip depends on installing fasteners in the right locations and driving them flush to the shingle surface.

Underdriven Fasteners

Underdriven fasteners will prevent the sealant strip from contacting overlying shingles, and the protruding fasteners can puncture and damage the overlying shingles. Dirt and debris accumulated on the sealant will also render it ineffective.

Overdriven Fasteners

Overdriven fasteners can dimple the shingles, preventing sealant transfer or cutting through the shingles.

Contaminated sealant strips on the shingle can never fully bond.

High Fastening

High fastening makes asphalt shingles less wind resistant. Installing nails one inch above the fastener line so that the nails only penetrate one shingle can lead to shingle slippage (shingles displaced from their original position) and lower wind resistance.

Non-Wind Related Problems with Asphalt Shingles

How well an asphalt shingle stands up to weather over time depends on the shingle's main elements: the volatiles, the shingle's ductility, and the transition temperature of the asphalt.

Loss of Volatiles Leads to Craze-Cracking of Shingles

Volatiles, which have a low boiling point, are added to the asphalt mixture to keep shingles flexible and waterproof. Over time, evaporation and moisture can dissipate the volatiles, causing the asphalt to dry, shrink, and crack (craze-cracking), allowing water to get beneath the roof system, damaging the building and roofing systems.

Improper Ductility makes Shingles Brittle

Ductility gives shingles their flexibility, allowing shingles to bend and return to their original shape without damage. Manufacturers add pulverized stone and polymers (fillers) to the asphalt to give the shingles ductility, strength, and impact resistance. Too little filler results in soft and flexible shingles, diminishing their wind resistance, causing them to fracture, crease, tear or pull over the heads of fasteners during and after installation. Too much filler makes shingles brittle and shortens their service life, often becoming damaged during transportation and installation. Asphalt shingles may contain up to 60 percent or more of filler.

Low Temperature Make Shingles Brittle

Transition temperature (a shingle’s softening point) is the temperature below which shingles lose their ductile properties and fracture more easily. Below the transition point, the asphalt shingles can scuff (loss granules) and mar (deformation of the surface of the asphalt) easily during installation.

The near roof edge shows scuffing from footfall.

High Temperatures Impact Integrity of Asphalt Shingles

High temperatures cause the shingles to soften. The repeated softening and hardening of the asphalt shingles causes them to dry out and become brittle. Brittle shingles will break at the edges or burn through in spots, allowing water to get beneath the roof system, damaging the building and roofing systems.

Loss of UV Protective Granules

Over time, the UV protective granules on the upper surface of asphalt shingles will loosen and fall away, allowing the UV rays to break down the asphalt.

Unventilated Roof Systems Can Rot an Asphalt Roof

A ventilated roof system releases heat and moisture from the attic and roof structures. Without proper ventilation, the excessive heat and moisture buildup will lower the felt roofing underlayment and reduce the asphalt shingles' service life.

Synthetic Slate Roof

For the past few decades, lightweight synthetic roofing materials have grown in popularity, mainly due to their aesthetic appeal of mimicking natural slate. However,SBS (styrene-butadiene-styrene) Class 4 impact-resistant synthetic slate roofs offer much more than good looks. They provide significant durability, weather-resistance, and a lifespan of over 50 years, with low maintenance and installation ease.

Cost

Synthetic-slate roofing costs more ($10 – $18 psf) than asphalt roofing. However, Class 4 impact-resistant synthetic slate shingles can lessen long-term maintenance costs and eliminate premature roof replacement, allowing homeowners to make up the higher initial costs quickly. Class 4 impact-resistant shingles also save homeowners money because they may get a discount on their homeowner’s insurance premium, and it increases a home's resale value. Manufacturers, like Brava Roof Tiles, produce synthetic roofing shingles entirely from recycled polymer materials, making them a green, eco-friendly, and beautiful roofing product.

Impact Resistance

Impact-resistant slate roofing stands up to wind, hail, rain, ice, and debris, providing superior protection to the home’s structure and interior, compared to asphalt shingles, saving homeowners on expensive repairs and possible roof replacement. Impact-resistant shingles offer several specific features that contribute towards a long-lasting, low-maintenance roof. They help ensure that a roof will maintain its integrity and strength against flying debris, winds, and hail up to 110 mph. Most impact-resistant shingles, like Brava synthetic slate roofing shingles, have a Class A fire rating.

Brava Synthetic Slate Roof vs. Asphalt Shingles

Asphalt roofing is a lower cost, attractive roofing product for many homes. However, problems during installation, deterioration of waterproofing and UV protection, and a lack of temperature resistance often leads to expensive roofing repairs and possibly, early roof replacement. In the worst case, a damaged roof can also lead to significant structural damage to your home.

Old World Slate synthetic roofing tiles from Brava Roof Tile are the best alternative to asphalt shingles. Durable synthetic composite tiles from Brava Roof Tile maintain their beauty and charm for the roof's lifetime with practically no maintenance. Class 4 impact-rated, Brava slate tiles will resist damage from wind, hail, water, fire, and extreme temperatures.

Lightweight synthetic roofing tiles install easily, and quickly, without all the installation problems of asphalt shingles. Installation of synthetic tiles involves easily field-cutting the synthetic slate shingles with a utility knife. Then, using a pneumatic nail gun and standard roofing nails, the shingles can be nailed in place.

For more information on the benefits of synthetic slate roofing, please contact the roofing experts at Brava Roof Tile today.